What Are the Key Benefits of Using F4BTMS450 Material in a 4-Layer RF PCB?

What Are the Key Benefits of Using F4BTMS450 Material in a 4-Layer RF PCB?

In the world of Radio Frequency (RF) and microwave electronics, the printed circuit board (PCB) substrate is far more than a passive platform for components; it is an integral part of the circuit's performance. Choosing the right material is critical, and for demanding applications, standard FR-4 is insufficient. The F4BTMS450 material represents a specialized high-frequency laminate that offers a suite of compelling advantages for a4-layer RF PCB design.

Here are the key benefits of using F4BTMS450:

1. Superior Signal Integrity with Stable Dielectric Constant

At RF frequencies, signal integrity is paramount. The dielectric constant (Dk orεr) of the substrate material directly controls the impedance of transmission lines (like microstrips and striplines) and the phase of signals.

- Tight Dk Tolerance: F4BTMS450 has a dielectric constant of 4.5 +/-0.09 at 10GHz. This exceptionally tight tolerance ensures that the impedance is consistent across the entire board and from one batch of boards to the next.

- Benefit: Engineers can design with confidence, achieving precise impedance matching (e.g., 50Ωlines) without unexpected variations that can cause signal reflections, loss of power, and degraded system performance.

2. Extremely Low Loss for Enhanced Efficiency

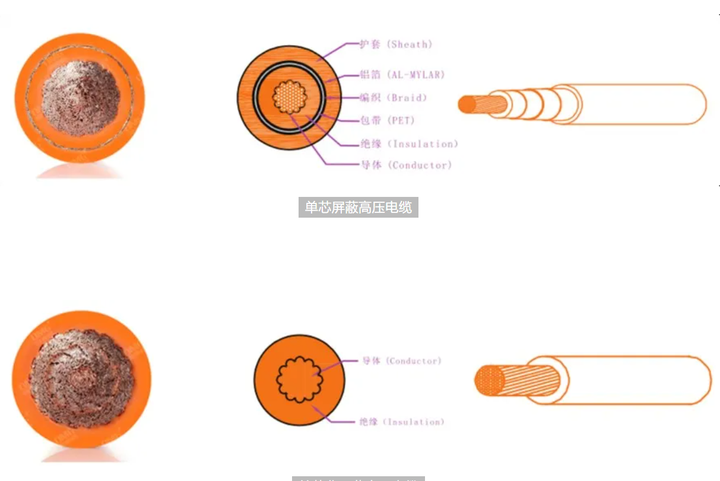

As signals travel through the 4-layer F4BTMS450 PCB, some energy is absorbed by the dielectric material and converted into heat. This is measured by the Dissipation Factor (Df) or loss tangent.

- Minimal Dielectric Loss: F4BTMS450 boasts an ultra-low dissipation factor of 0.0015 at 10GHz. This is an order of magnitude lower than standard FR-4.

Benefit: For a 4-layer RF PCB, this translates to:

- Higher Efficiency: Less signal power is lost, which is crucial for battery-operated devices and high-power transmitters.

- Improved Signal-to-Noise Ratio (SNR): Cleaner signals with less degradation over distance.

- Better System Performance: In applications like radar and satellite communications, low loss directly increases range and sensitivity.

3. Exceptional Thermal and Dimensional Stability

RF systems, especially power amplifiers, generate heat, and equipment often operates in harsh environments with wide temperature swings.

- Low Coefficient of Thermal Expansion (CTE): F4BTMS450 has a CTE of 12/12/45 ppm/°C (x/y/z). This low and balanced expansion profile is close to that of copper, reducing stress on plated through-holes (vias).

- Stable Dk over Temperature: Its thermal coefficient of Dk is a low -58 ppm/°C. This means the dielectric constant remains stable over a wide temperature range (-55°C to 150°C).

Benefit: The 4-layer PCB structure remains mechanically reliable, preventing via cracking and delamination. Electrically, the circuit performance (e.g., filter center frequency, phase response) remains predictable and stable regardless of operational temperature, which is vital for aerospace and defense applications.

4. High Reliability for Demanding Environments

The operational environment for many RF applications is unforgiving. F4BTMS450 is engineered to meet these challenges.

- Low Moisture Absorption (0.08%): Moisture ingress can drastically alter a material's Dk and increase loss. The very low moisture absorption of F4BTMS450 high frequency PCB ensures stable electrical performance even in humid conditions.

- UL-94 V0 Flammability Rating: The material is self-extinguishing, enhancing the safety and reliability of the end-product.

Benefit: This combination makes the resulting 4-layer PCB highly reliable and suitable for critical systems in aerospace, spaceflight, and military radar, where failure is not an option.

5. Optimal Performance for Complex, Dense 4-Layer Designs

The specific construction of a 4-layer board using F4BTMS450 leverages all the benefits above into a practical, high-performance multilayer solution.

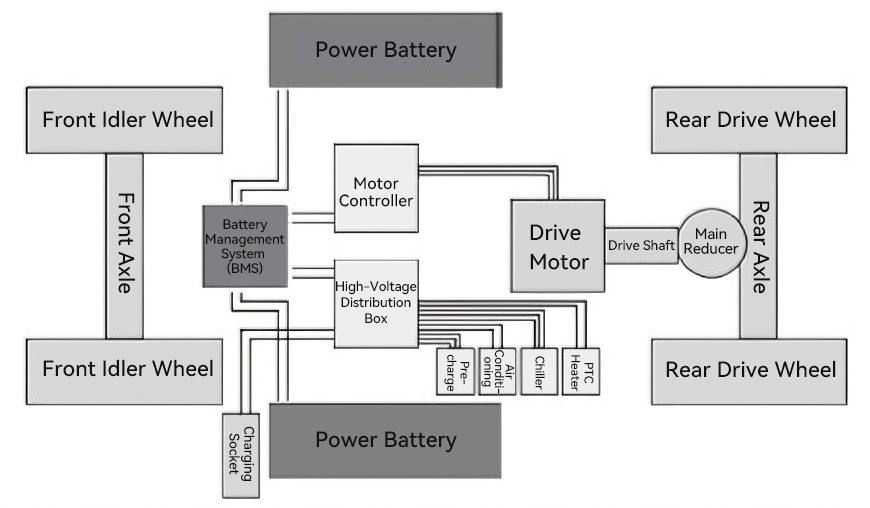

- Improved EMI Shielding: A typical4-layer stackup (Signal-Ground/Power-Signal) allows for dedicated ground planes. These planes act as shields, containing RF energy within the board and protecting sensitive signals from external noise.

- Enhanced Power Integrity: The solid internal power plane provides a low-inductance power distribution network, which is crucial for stable voltage to high-speed digital and RF components.

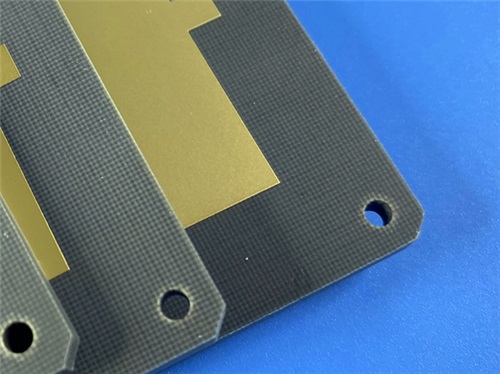

- Material Consistency in Multilayer Bonding: The use of compatible prepreg (likeRO4450F) in the stackup ensures a homogeneous dielectric environment, maintaining consistent electrical properties throughout all four layers.

Conclusion: A Foundation for High-Frequency Success

In summary, selecting F4BTMS450 for a 4-Layer RF PCB is a strategic decision to build your design on a foundation of performance, stability, and reliability. Its key benefits—stable dielectric constant, extremely low loss, outstanding thermal performance, and high environmental resilience—directly address the most critical challenges in RF and microwave design. By minimizing electrical losses and maintaining predictable behavior under stress, this material enables the creation of superior, high-performance systems for the most demanding applications in aerospace, telecommunications, and defense.