Exploring the Interconnection between Radio Communication Vans and Fusion Splicers

In the realm of modern telecommunications infrastructure maintenance and deployment, two essential tools play vital roles in distinct yet interconnected functions—Radio Communication Vans and Fusion Splicers. Both are central to ensuring efficient, reliable, and seamless operation of communication networks, each with its unique capabilities that contribute to the overall functionality and resilience of the infrastructure.

Radio Communication Vans, also known as Mobile Communications Units, are versatile vehicles equipped with advanced radio communication equipment to facilitate seamless and reliable wireless communication in diverse scenarios. These vans serve as mobile command centers capable of establishing communication links in emergency situations, remote locations, events, or areas with limited existing infrastructure.

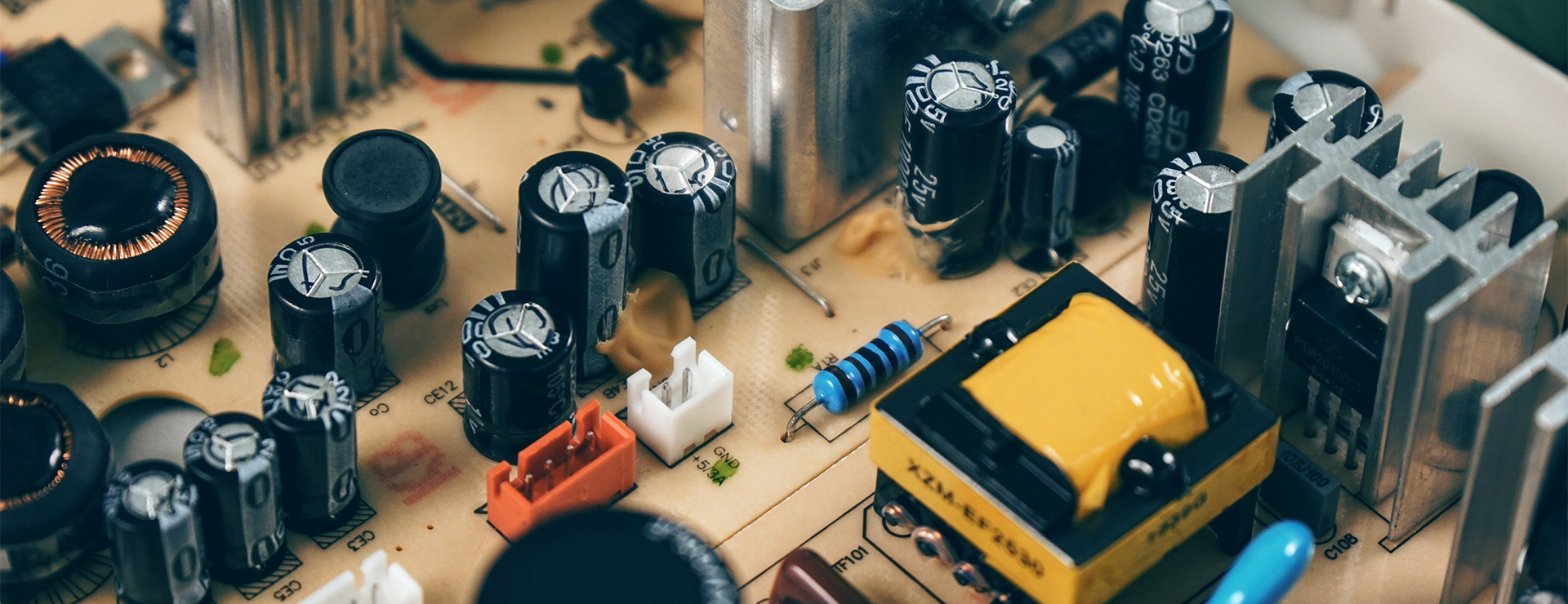

Equipped with a range of communication technologies such as radios, antennas, satellite dishes, and power supplies, Radio Communication Vans provide critical communication services for public safety, disaster response, broadcasting, event management, and various other applications. These vans act as mobile hubs that enable communication between field personnel, command centers, and other relevant stakeholders, ensuring coordination, information dissemination, and connectivity in challenging environments.

Fusion Splicers are essential tools used in the installation and maintenance of fiber optical networks. These devices enable technicians to create permanent, low-loss connections between optical fibers by fusing the fiber ends together. By precisely aligning and melting the fibers, fusion splicers ensure efficient light transmission across the network, minimizing signal loss and maximizing network performance.

Fusion splicing plays a critical role in expanding and upgrading fiber optic infrastructures by enabling the seamless connection of optical fibers, creating a robust network that can meet the demands of high-speed data transmission and telecommunications services. These splicers are indispensable in maintaining network integrity, reducing signal attenuation, and minimizing service disruptions in fiber optic communication networks.

The relationship between Radio Communication Vans and Fusion Splicers becomes apparent in scenarios where the installation and maintenance of fiber optic communication links are required in remote, temporary, or challenging environments. In such situations, Radio Communication Vans provide the necessary infrastructure for on-site operations, serving as a mobile base for technicians to deploy and coordinate their activities.

Fusion Splicers, on the other hand, play a crucial role in establishing high-quality fiber optic connections that enable reliable data transmission through the network. Technicians working from Radio Communication Vans can use Fusion Splicers to create durable and low-loss fiber optic splices, ensuring seamless connectivity and optimal performance of the communication links.

In conclusion, the collaboration between Radio Communication Vans and Fusion Splicers represents a synergy between mobile communication infrastructure and fiber optic network maintenance. By leveraging the capabilities of both tools, telecommunications operators can enhance their operational efficiency, extend their network reach, and ensure robust and reliable communication services in diverse environments. The interconnection between Radio Communication Vans and Fusion Splicers underscores the importance of integrated solutions in modern telecommunications, where mobility, connectivity, and reliability are paramount in sustaining effective communication.