What Makes TMM 10i the Ideal Choice for High-Frequency PCB Applications?

What Makes TMM 10i the Ideal Choice for High-Frequency PCB Applications?

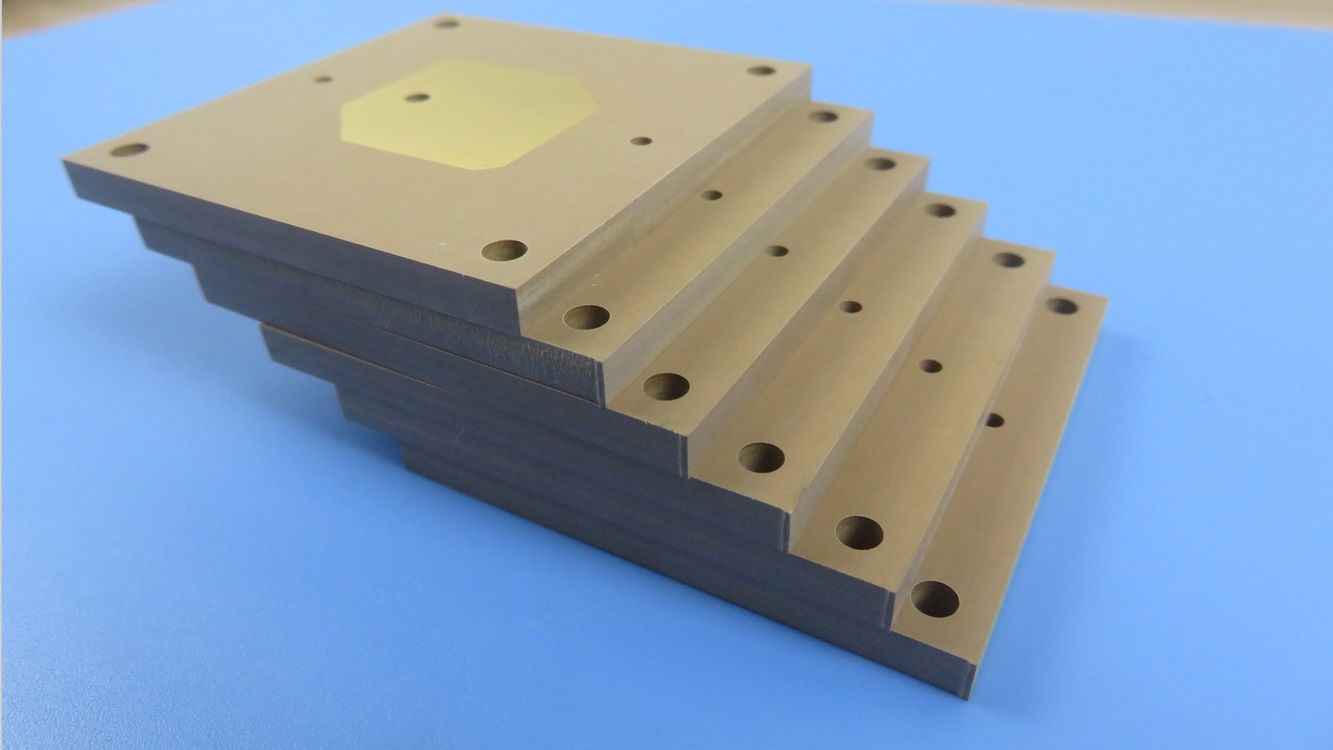

In the demanding world of high-frequency electronics, the choice of printed circuit board (PCB) substrate material is paramount to the performance, reliability, and success of the final product. Rogers Corporation's TMM 10i high-frequency laminate stands out as a premier ceramic thermoset polymer composite, engineered specifically for superior performance in stripline and microstrip applications requiring exceptional plated through-hole reliability. This advanced material masterfully blends the most desirable properties of ceramic and PTFE-based substrates. A significant advantage is its compatibility with soft substrate processing methodologies, which streamlines the manufacturing process and makes fabrication more straightforward and efficient compared to other high-performance materials.

A defining characteristic of TMM 10i laminates is their isotropic dielectric constant and matching coefficients of thermal expansion (CTE). This CTE is meticulously engineered to closely mirror that of copper, a fundamental feature that promotes the creation of highly robust and reliable plated through holes. This compatibility drastically minimizes the risk of via failure due to thermal stress and significantly reduces etch shrinkage, ensuring the structural integrity of the PCB throughout its lifecycle. Furthermore, Rogers TMM 10i offers a remarkable thermal conductivity that is nearly twice that of standard PTFE/ceramic laminates. This enhanced property drastically improves the board's ability to dissipate heat, a critical factor in maintaining performance and preventing thermal degradation in high-power applications.

Key Features and Unmatched Benefits

The TMM 10i material brings a host of benefits that directly translate into enhanced product design:

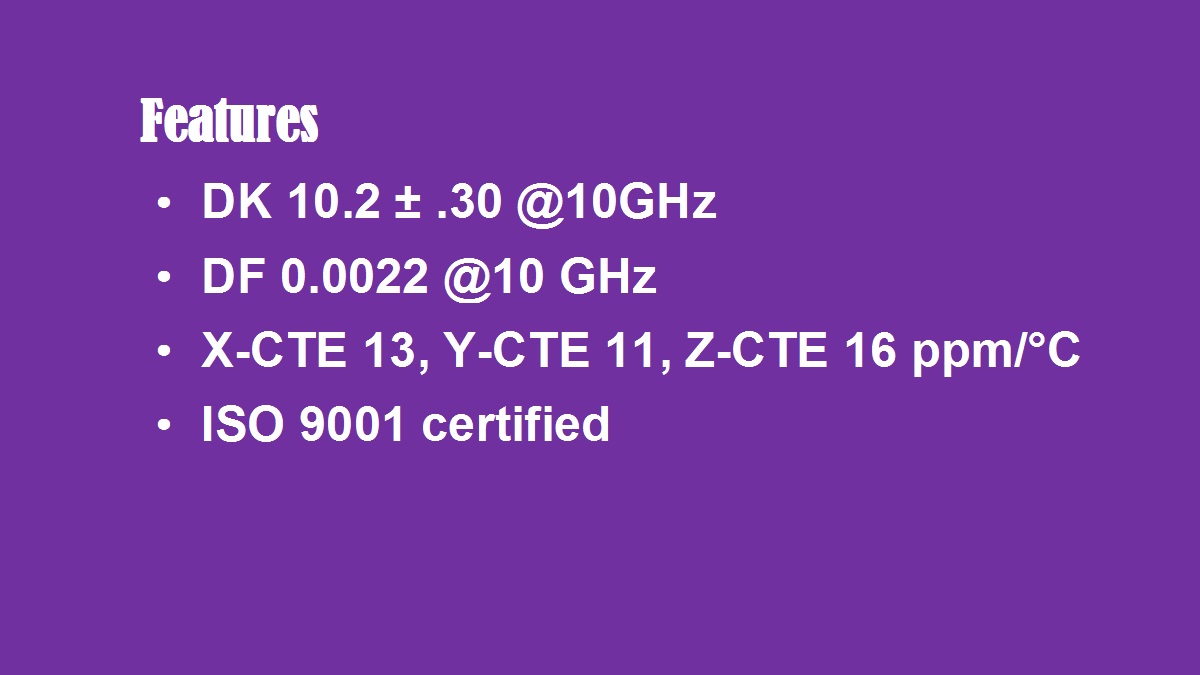

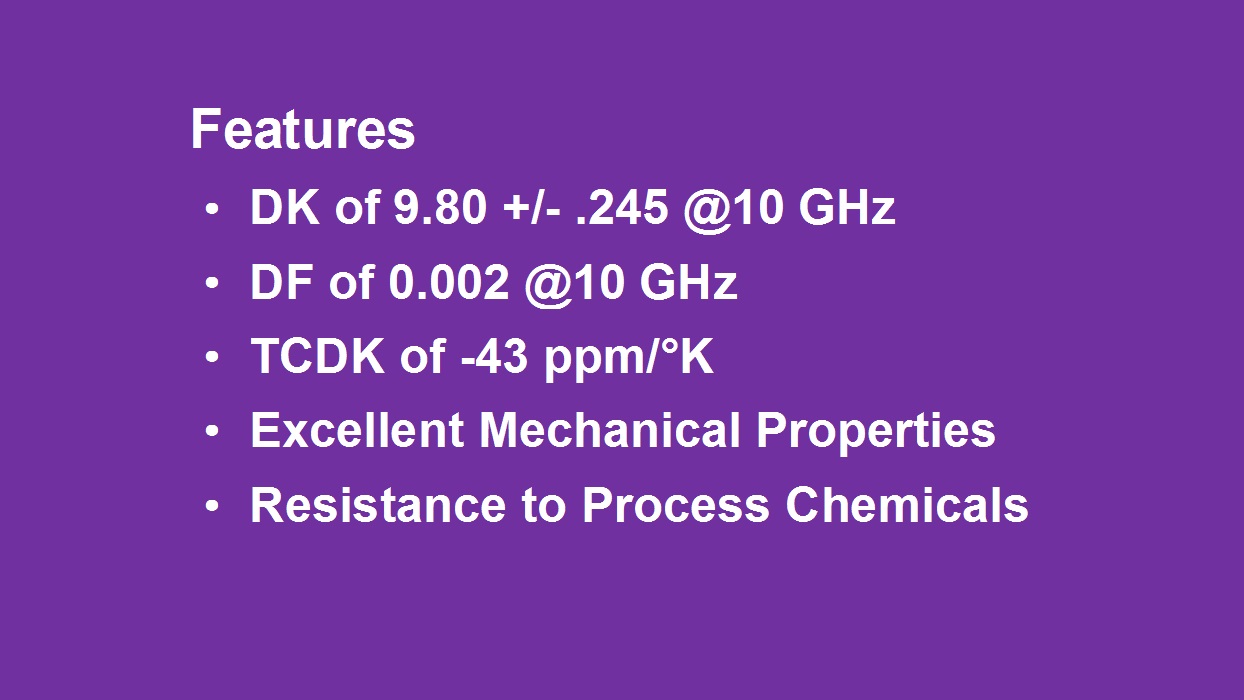

1) High Dielectric Constant (Dk): With a stable Dk of 9.80±0.245, TMM 10i allows designers to increase the capacitance of capacitors integral to the circuit. This enables the creation of more compact component and board designs without sacrificing electrical performance, a crucial advantage in space-constrained, high-frequency devices where efficiency is non-negotiable.

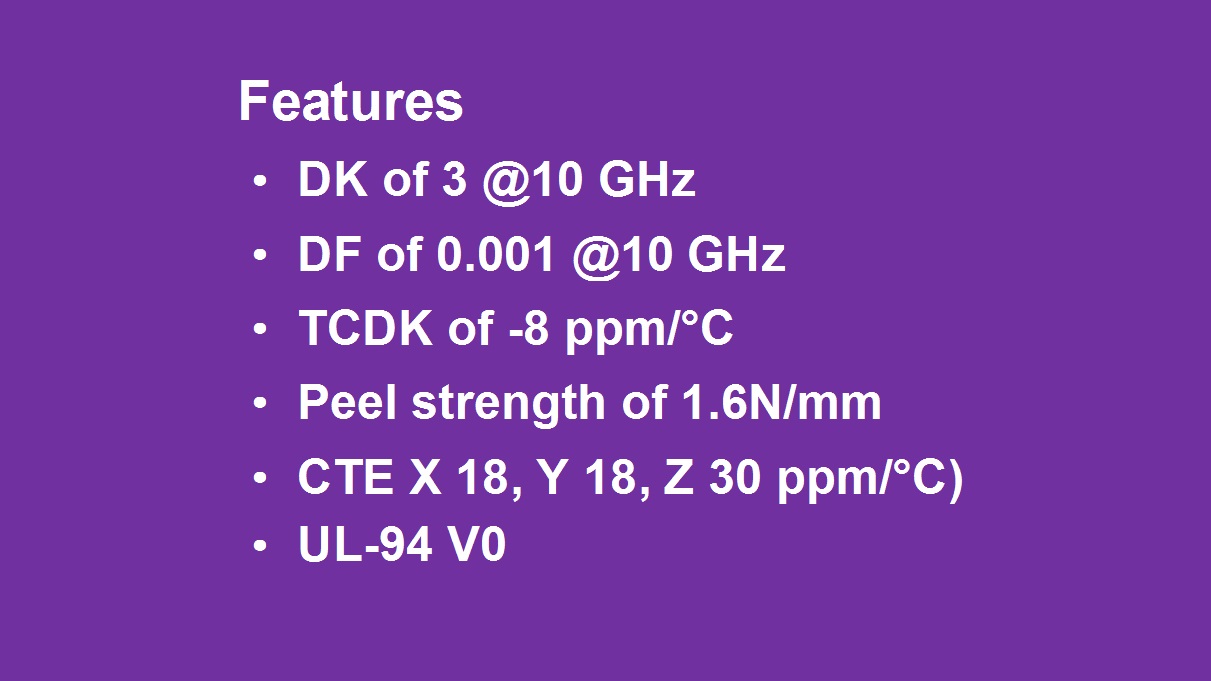

2) Low Dissipation Factor (Df): The laminate boasts an impressively low dissipation factor of just 0.0020 at 10 GHz. This guarantees minimal dielectric signal loss, drastically reducing distortion and attenuation. The result is cleaner signal transmission and enhanced overall system performance for sensitive RF and microwave circuits.

3) Exceptional Thermal Stability: The thermal coefficient of the dielectric constant is a minimal -43 ppm/°K. Coupled with its copper-matched CTE, this ensures that the electrical properties remain stable across a wide temperature range. This excellent thermal management is vital for applications subjected to fluctuating operational environments.

4) Superior Mechanical Properties: TMM 10i is highly resistant to creep and cold flow, safeguarding the physical and electrical integrity of the PCB even in the most demanding mechanical and environmental conditions. This ensures long-term reliability and consistent performance.

5) Chemical Resistance: Its inherent resistance to a wide array of process chemicals used in PCB fabrication minimizes potential damage during production. This not only improves yields but also streamlines the entire manufacturing process, reducing time and cost.

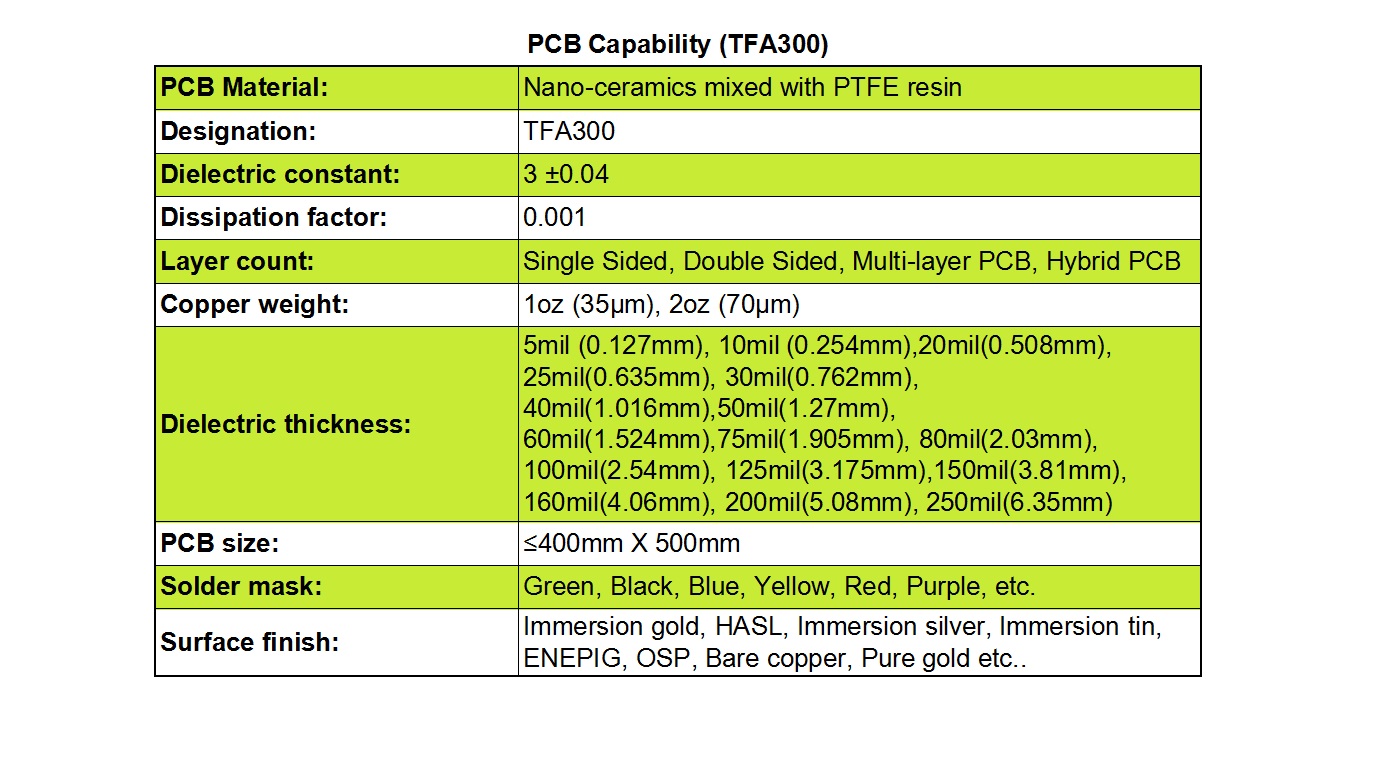

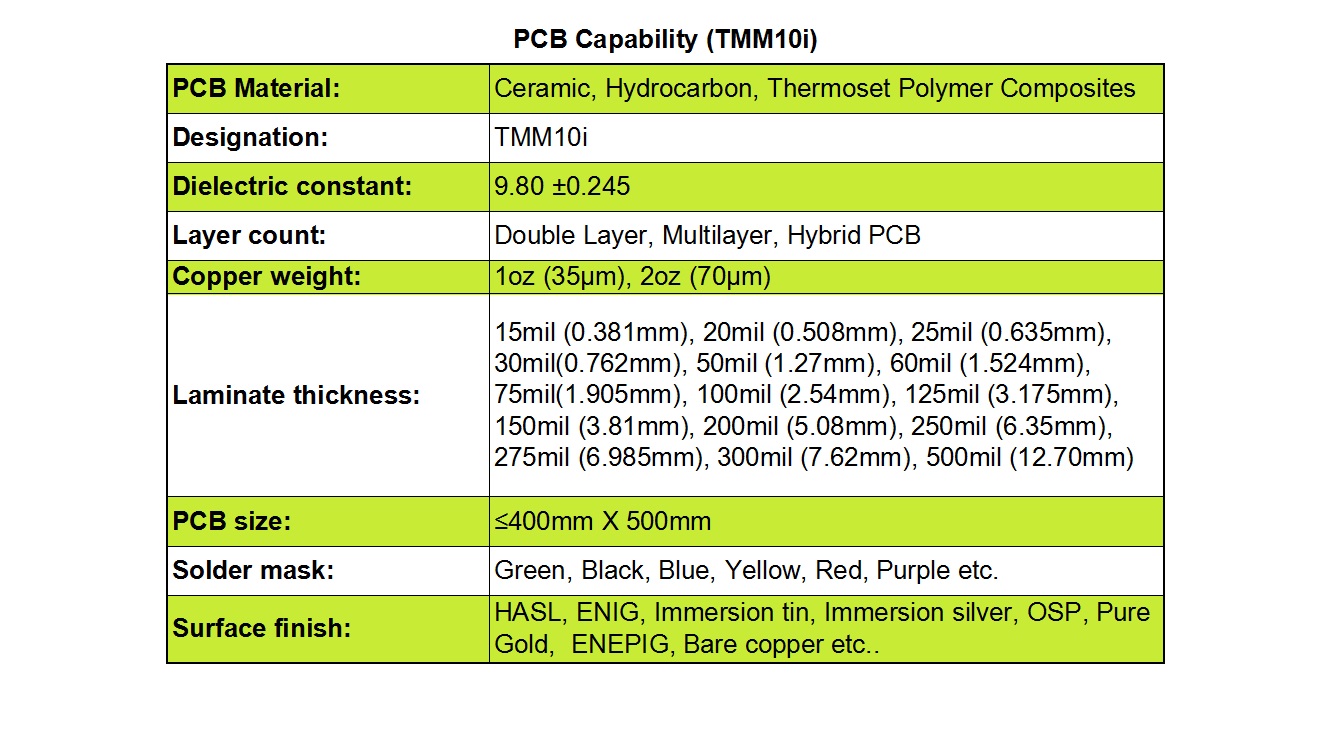

Our Advanced PCB Manufacturing Capabilities

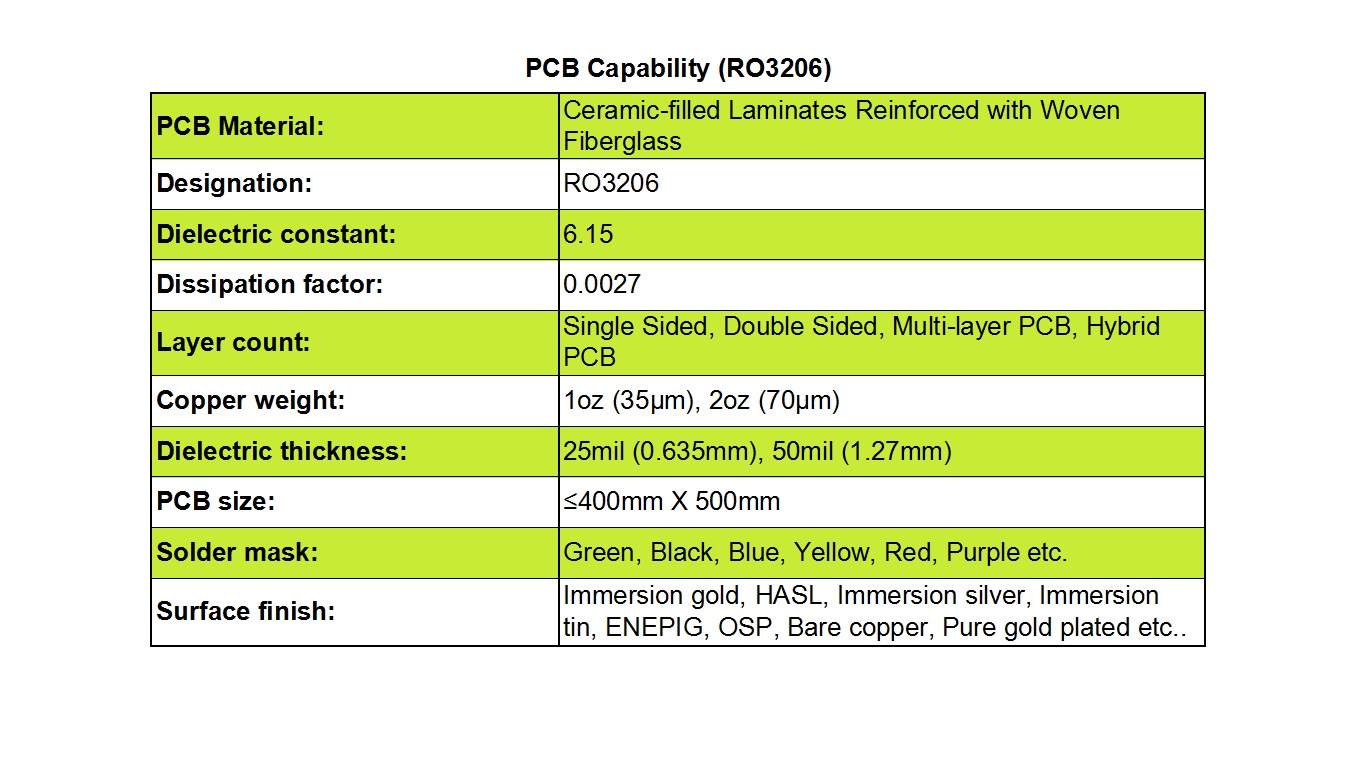

To fully leverage the exceptional properties of TMM 10i substrate, partnering with a manufacturer with the right expertise and capabilities is essential. We provide comprehensive PCB solutions tailored to your specific high-frequency requirements:

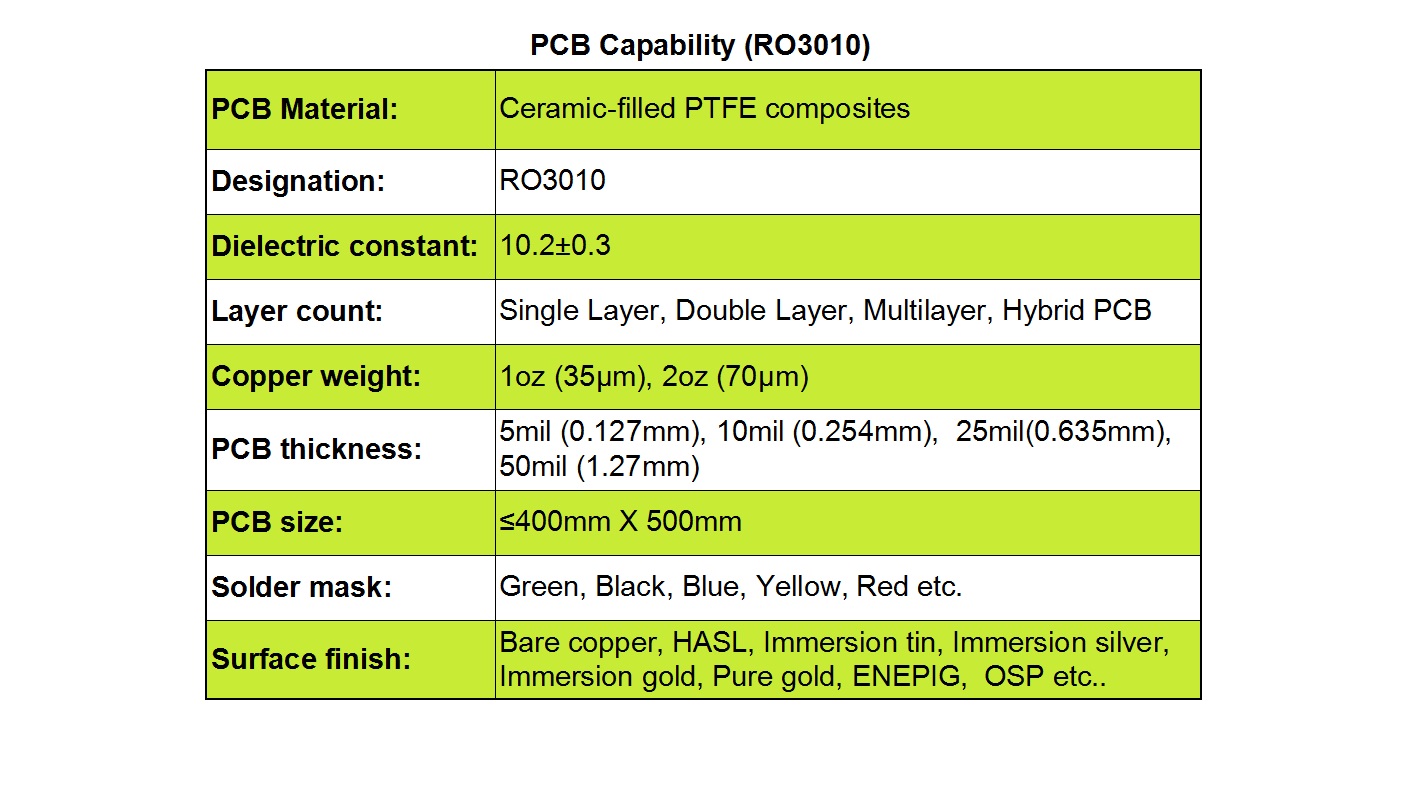

Configuration Variety: We support double-layer, multi-layer, and hybrid PCB configurations, offering the flexibility needed for complex designs.

Copper Weights: Standard copper weights of 1 oz (35 µm) and 2 oz (70 µm) are available to cater to different current-carrying capacity and power requirements.

Thickness Range: We offer a broad spectrum of thickness options, from a thin 15 mil (0.381 mm) to a substantial 500 mil (12.70 mm), to meet precise impedance and mechanical specifications.

Board Dimensions: Our manufacturing supports a maximum PCB size of 400 mm x 500 mm, providing ample space for sophisticated and large-scale circuit designs.

Aesthetic Flexibility: Choose from a wide selection of solder mask colors including green, black, blue, yellow, red, and purple to meet branding or coding needs.

Surface Finishes: To enhance performance, solderability, and durability, we offer a complete range of surface finishes: HASL, immersion gold (ENIG), immersion tin, immersion silver, OSP, pure gold plating, ENEPIG, and bare copper.

Diverse Application Fields

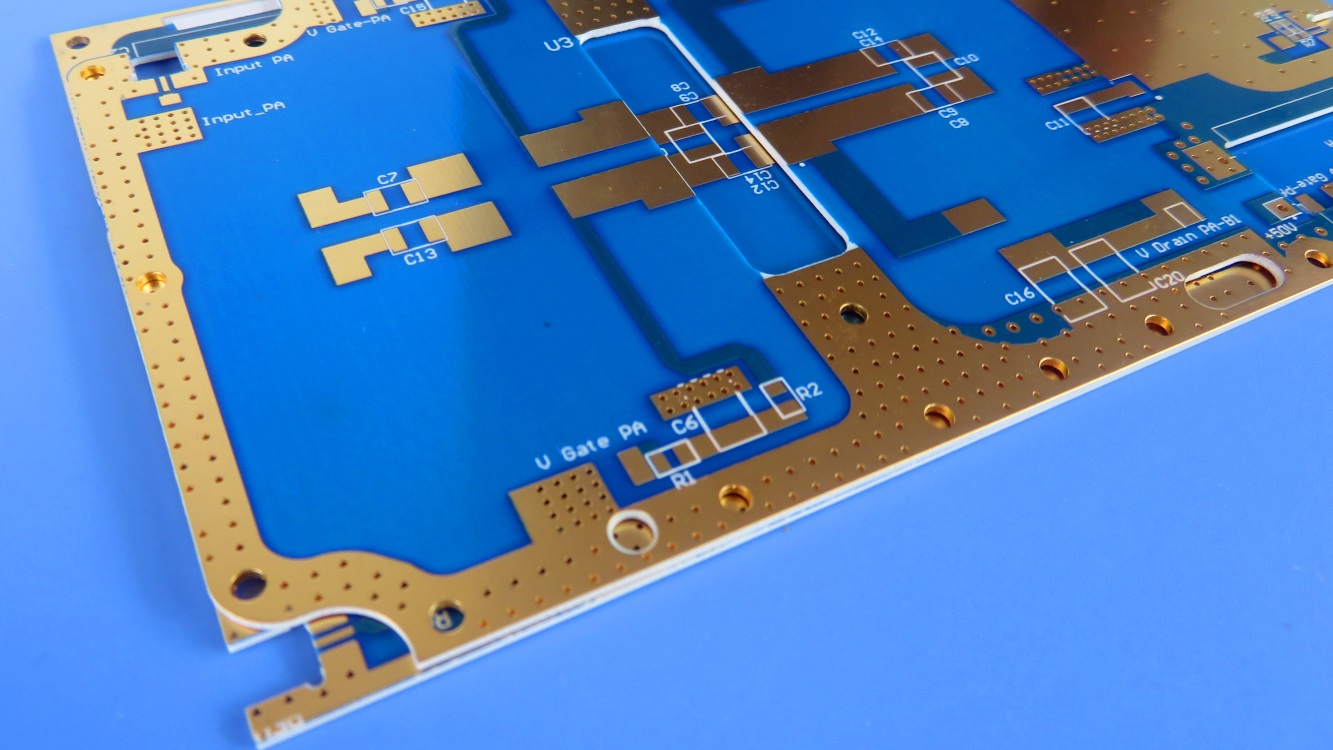

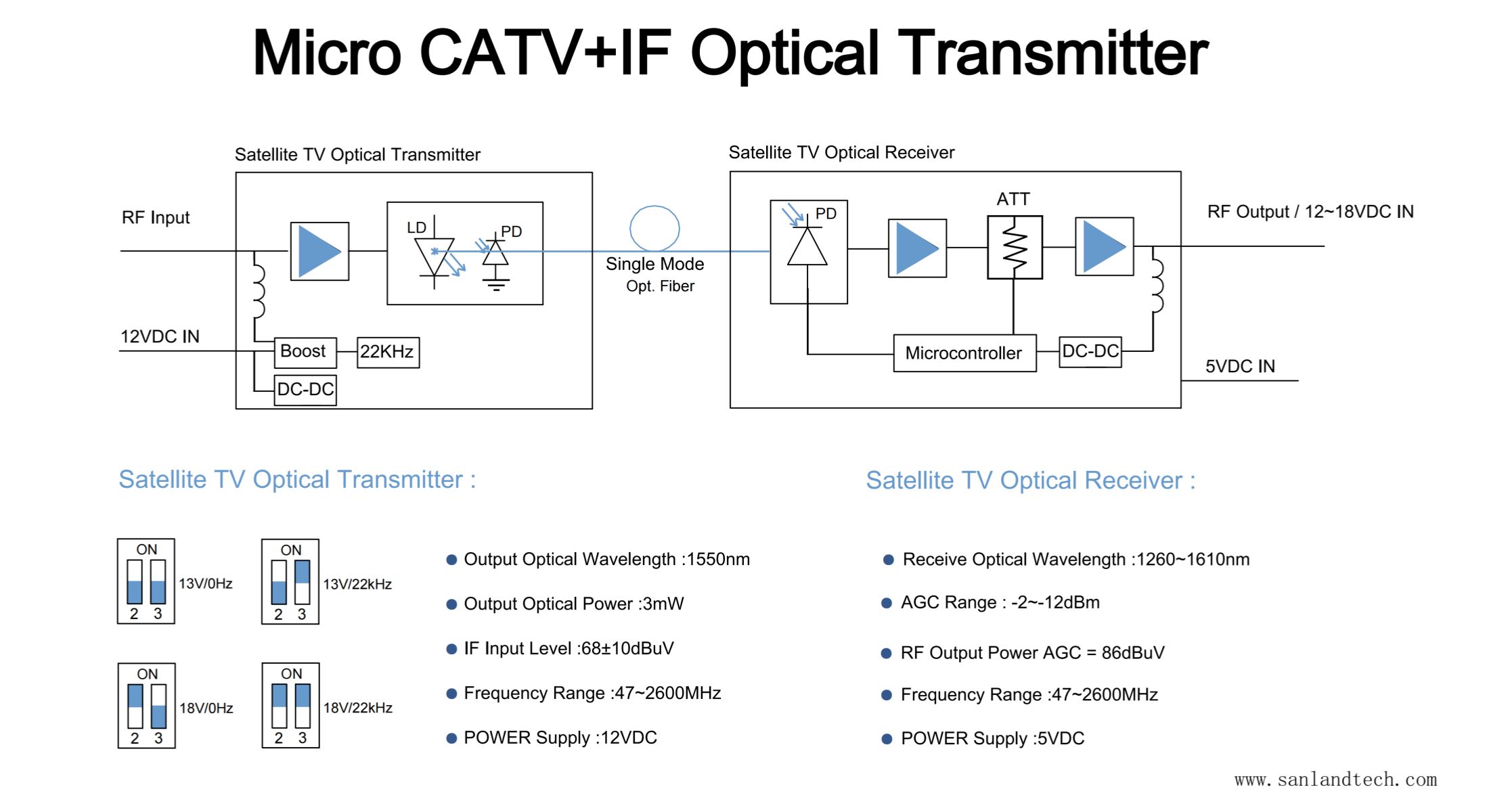

The versatile combination of electrical and thermal properties makes TMM 10i PCBs an ideal solution for a broad spectrum of RF and microwave applications. They deliver outstanding performance in critical components such as power amplifiers, filters, and couplers. This makes them particularly well-suited for satellite communication systems, GPS antenna arrays, and radar systems. Additional common applications include patch antennas, dielectric polarizers, and high-frequency chip testers, where signal integrity and thermal management are of utmost importance.

By selecting TMM 10i high frequency PCB for your next project, you are investing in a material that provides a perfect synergy of electrical performance, thermal resilience, and manufacturing reliability. Contact us today to discuss how we can transform your high-frequency design concepts into reality with our advanced TMM 10i PCB solutions.