Why Choose RO4360G2 Laminates for Your Next High-Frequency PCB Project?

Why Choose RO4360G2 Laminates for Your Next High-Frequency PCB Project?

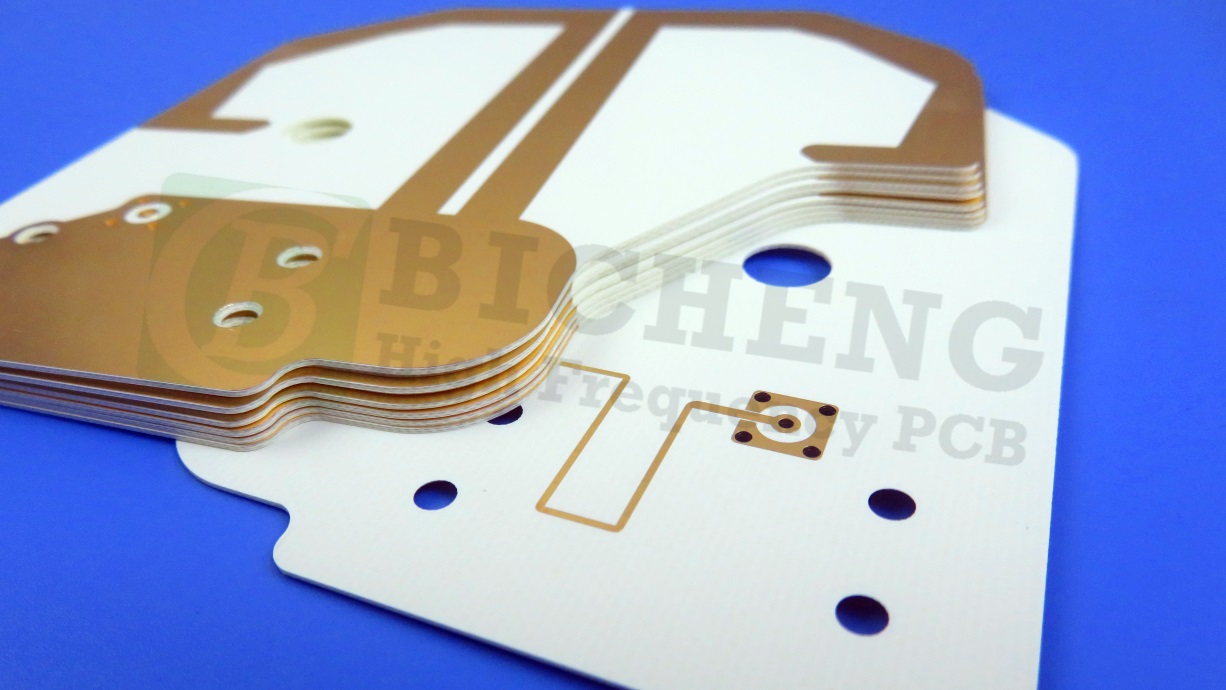

In the rapidly evolving world of high-frequency electronics, selecting the right printed circuit board (PCB) material is crucial to achieving optimal performance, reliability, and cost-efficiency. Rogers RO4360G2 laminates stand out as a premier choice for high-frequency applications, offering an exceptional combination of electrical properties, thermal management, and manufacturability. These glass-reinforced, hydrocarbon ceramic-filled thermoset materials are engineered to deliver superior performance while simplifying the fabrication process.

A groundbreaking feature of Rogers 4360G2 laminates is that they represent the first high dielectric constant (Dk) thermoset materials that can be processed similarly to conventional FR-4. This compatibility significantly eases the transition for designers and manufacturers looking to leverage high-Dk PCB materials without investing in new processing techniques or equipment. Furthermore, these laminates support lead-free assembly processes and provide enhanced rigidity. This improved stiffness is particularly beneficial in multi-layer board constructions, where it contributes to better dimensional stability and easier handling, ultimately reducing both material and fabrication costs.

Another notable advantage is the compatibility of RO4360G2 with other materials in the RO4000® series. It can be seamlessly integrated with RO4400™series prepregs and lower-Dk RO4000® laminates in multi-layer designs. This interoperability offers designers greater flexibility, enabling the creation of sophisticated, high-performance hybrid PCB structures tailored to specific application requirements.

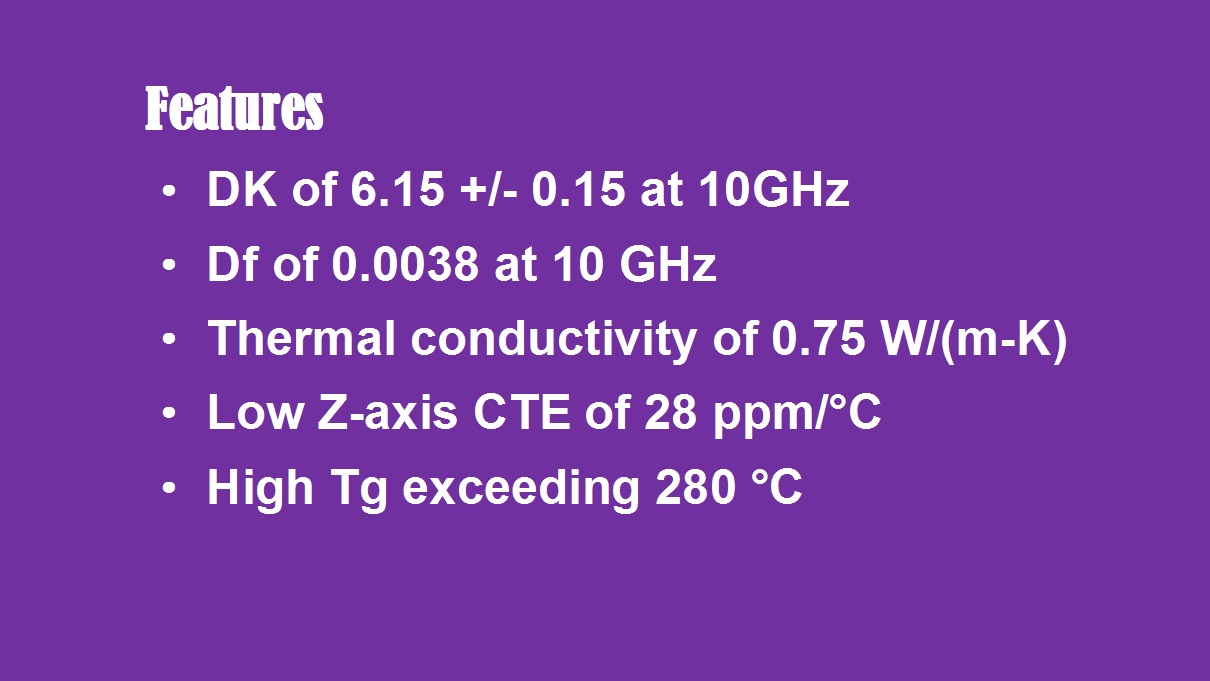

Key Features of RO4360G2 High Frequency Laminates

The RO4360G2 substrate boasts a high dielectric constant (Dk) of 6.15, with a design Dk of 6.4. This high Dk allows designers to reduce the physical dimensions of circuits, which is particularly advantageous in applications where minimizing size and controlling costs are critical.

With an exceptionally low dissipation factor of 0.0038 at 10 GHz, these laminates ensure minimal signal loss and outstanding signal integrity, making them ideal for high-speed and high-frequency applications.

Thermal management is another area where RO4360G2 excels. It offers a high thermal conductivity of 0.75 W/(m·K), which facilitates efficient heat dissipation away from critical components, thereby enhancing the overall reliability and longevity of the circuit.

The RO4360G2 material also exhibits a low Z-axis coefficient of thermal expansion (CTE) of 28 ppm/°C. This property ensures dimensional stability under thermal stress and significantly improves the reliability of plated through-hole (PTH) interconnections.

Finally, the RO4360G2 PCB features a high glass transition temperature (Tg) exceeding 280°C as measured by TMA (Thermomechanical Analysis). This high Tg enhances the material’s durability and performance stability even in the most demanding operating environments.

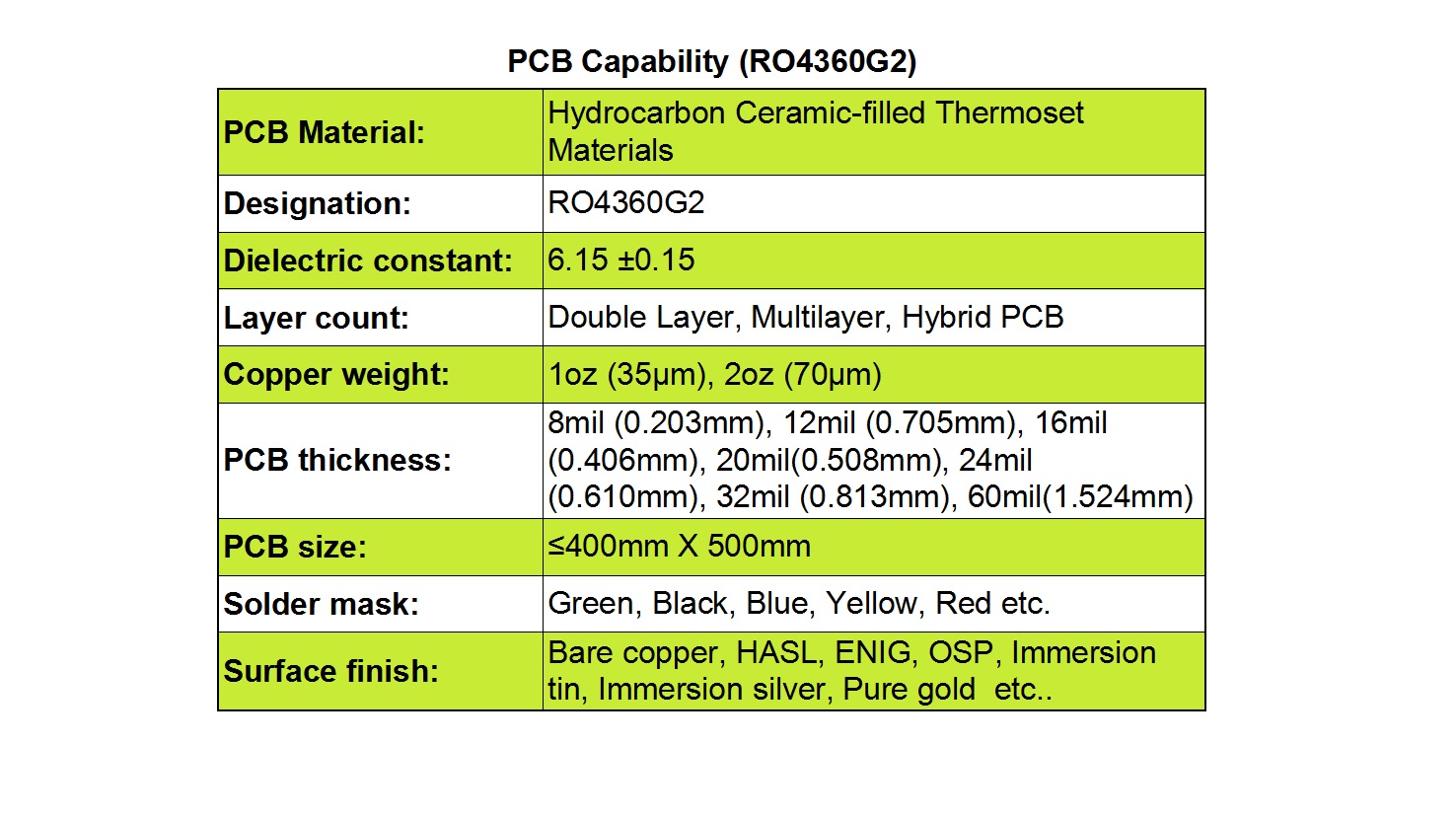

PCB Manufacturing Capabilities with RO4360G2

Our state-of-the-art manufacturing facilities are fully equipped to produce a wide variety of PCBs using RO4360G2 laminates. We specialize in manufacturing double-layer, multi-layer, and hybrid PCBs, enabling us to meet diverse design complexities and performance requirements.

We offer flexible copper weight options, including 1oz (35µm) and 2oz (70µm), allowing you to optimize current carrying capacity and signal performance based on your specific design needs.

A comprehensive range of standard thicknesses is available, such as 8mil (0.203mm), 12mil (0.305mm), 16mil (0.406mm), 20mil (0.508mm), 24mil (0.610mm), 32mil (0.813mm), and 60mil (1.524mm), providing the flexibility to meet various mechanical and electrical constraints.

Our production capabilities support PCB sizes up to 400mm x 500mm, accommodating both compact and larger form factor designs.

To suit both functional and aesthetic preferences, we provide a wide selection of solder mask colors, including green, black, blue, yellow, red, and others.

We also offer an extensive array of surface finishes, including Bare Copper, HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), Immersion Tin, Immersion Silver, and Pure Gold, ensuring the optimal finish for your application’s performance and reliability needs.

Typical Applications

RO4360G2 high-frequency PCBs are widely used in demanding RF and wireless communication applications. Common uses include base station power amplifiers and small cell transceivers, where their excellent electrical properties and thermal performance are essential for ensuring signal clarity, power efficiency, and long-term reliability in critical infrastructure.