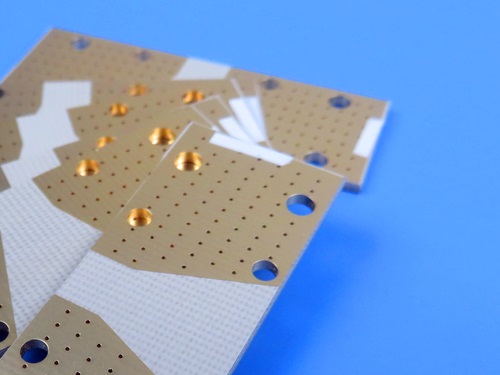

How Does an RF-10 PCB Combine High Thermal Conductivity for Reliable RF Circuits?

How Does an RF-10 PCB Combine High Thermal Conductivity for Reliable RF Circuits?

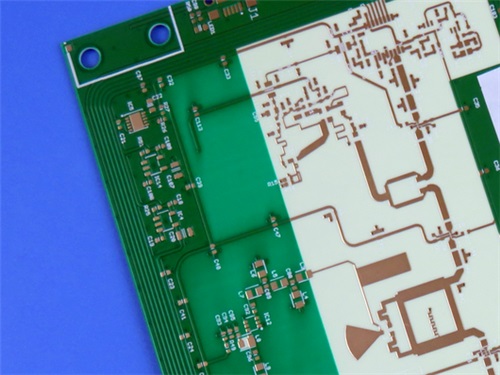

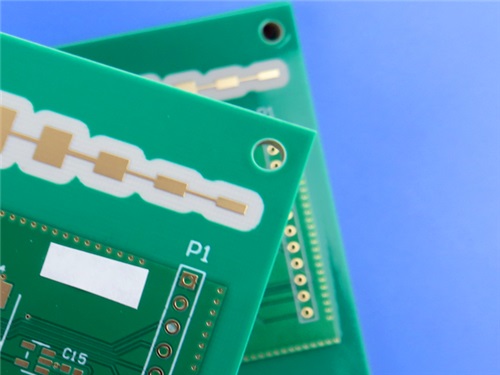

In high-frequency circuit design, reliability is not merely about robust construction—it’s about maintaining precise electrical performance under varying thermal, mechanical, and environmental stresses. The RF-10 PCB with a 25mil core and Immersion Gold finish excels in this regard by integrating two cornerstone material properties: high thermal conductivity and exceptional dimensional stability. Here’s how this combination ensures long-term reliability in demanding RF applications.

1. The Role of High Thermal Conductivity (0.85 W/mk)

Mechanism:

Unlike standard FR-4 laminates,Taconic RF-10 is a ceramic-filled PTFE composite. The ceramic particles (typically aluminum oxide or similar) dispersed within the polymer matrix create efficient pathways for heat transfer. This gives the unclad laminate a thermal conductivity of 0.85 W/mk, which is significantly higher than that of conventional high-frequency substrates.

Benefits for RF Circuit Reliability:

Effective Heat Dissipation: Active components (e.g., power amplifiers, LNAs) and passive dissipative elements generate heat during operation. TheRF-10 substrate acts as a lateral heat spreader, drawing heat away from localized hotspots. This prevents excessive temperature rise that could:

Shift component operating points.

Degrade solder joint integrity.

Accelerate aging of the material itself.

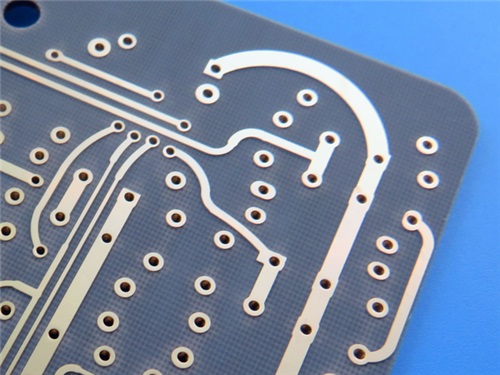

Reduced Thermal Gradient: A more uniform board temperature minimizes the risk of thermally-induced stress fractures in solder joints and plated through-holes (vias), which are critical for the 44 vias and 41 through-hole pads in a typical design using this board.

Enhanced Power Handling: For circuits handling moderate power levels (e.g., in power dividers or antenna feed networks), better heat dissipation allows for safer, more reliable operation without derating.

2. The Critical Importance of Dimensional Stability (Low CTE & Moisture Resistance)

Mechanism:

Dimensional stability in RF-10 Taconic RF PCB Circuit Board is achieved through two key factors:

Ceramic Filler: The inorganic ceramic filler has a inherently low coefficient of thermal expansion (CTE).

Woven Fiberglass Reinforcement: The thin glass fabric provides a rigid, stable scaffold that constrains the polymer's natural tendency to expand.

This results in remarkably low CTE values:

x-CTE: 16 ppm/°C

y-CTE: 20 ppm/°C

z-CTE: 25 ppm/°C

Furthermore, the PTFE-based matrix has very low moisture absorption (0.08%), preventing swelling and property changes in humid environments.

Benefits for RF Circuit Reliability:

Stable Impedance and Resonance: The core function of an RF circuit (e.g., a filter or antenna) depends on precise physical dimensions. A trace's width and its distance to the ground plane define its characteristic impedance. With low in-plane (x, y) CTE, the geometry of critical transmission lines (like microstrips on this 2-layer board) remains constant across temperature fluctuations, ensuring minimal drift in impedance and resonant frequency.

Via and Plated Hole Integrity: The matched CTE between the RF-10 core and the copper plating (via plating thickness: 20μm) reduces cyclical stress on the barrel of the vias during thermal cycling. This dramatically lowers the risk of interconnect failure—a common reliability issue in less stable substrates.

Improved Assembly and Operational Yield: A board that doesn't warp or expand excessively during the solder reflow process (which involves high temperatures) ensures better solder paste deposition and component alignment. This leads to fewer defects and stronger mechanical bonds.

3. Synergistic Effect: How They Work Together for Ultimate Reliability

The true reliability advantage emerges from the synergy between thermal conductivity and dimensional stability:

Preventing Thermal Runaway Scenarios: High thermal conductivity quickly removes heat, limiting the board's overall temperature rise. Because dimensional change (expansion) is directly proportional to temperature change (ΔT), a lower operatingΔT directly results in less physical expansion. The low CTE then ensures that the minimal expansion that does occur is itself highly constrained.

Maintaining Performance in Real-World Environments: Consider an aircraft collision avoidance system or an outdoor GPS antenna. The board must operate from cold high-altitude skies to sun-baked enclosures. The RF-10 Taconic PCB manages this by:

Efficiently dissipating internal heat from components.

Resisting expansion/contraction from external ambient changes.

This dual action keeps the electrical phase length, impedance, and grounding consistent, so the circuit performs identically at -40°C as it does at +85°C.

Long-Term Durability: The reduction in cyclical thermal stress on copper traces, vias, and component joints minimizes fatigue-related failure mechanisms. This leads to a longer mean time between failures (MTBF), which is paramount for aerospace, defense, and satellite applications where repair is impossible.

Conclusion: A Foundation Built for Rigorous Demands

The RF-10 2-layer PCB is more than just a platform for components; it is a stable, thermally-competent foundation engineered for the rigors of RF service. By combining high thermal conductivity (0.85 W/mk) for proactive heat management with exceptional dimensional stability (low CTE & moisture absorption) for geometric and electrical consistency, it directly addresses the primary physical threats to RF circuit reliability. This allows designers to focus on pushing performance boundaries, confident that their underlying substrate will not be the source of field failures, signal drift, or unexpected performance degradation. For missions where failure is not an option, this material synergy is not just a benefit—it is a requirement.