In the modern era of security and logistics, Radio Frequency Identification (RFID) technology has transitioned from a high-end luxury to a fundamental necessity. Whether you are managing a corporate office, a gated residential community, or a high-traffic hospitality venue, selecting the right credentials is the cornerstone of a functional access control system.

However, the market is saturated with various chips, frequencies, and materials. Choosing the wrong card can lead to hardware incompatibility, security vulnerabilities, or a poor user experience. This guide will walk you through everything you need to know to select the ideal Blank RFID cards for your specific project needs.

1. Understanding the Frequency Landscape

The first and most critical step in choosing an RFID card is matching the frequency to your reader hardware. RFID generally operates across three primary frequency bands, each with distinct characteristics:

-

Low Frequency (LF - 125 kHz):This is the traditional standard for basic proximity access. It offers a short read range and lacks sophisticated encryption. It is ideal for low-security environments where the primary goal is convenience rather than preventing high-tech cloning.

-

High Frequency (HF - 13.56 MHz):This is the most common frequency for secure access control today. It includes technologies like MIFARE and DESFire. HF cards support data storage and encrypted communication, making them the industry standard for corporate offices and government buildings.

-

Ultra-High Frequency (UHF - 860-960 MHz):UHF cards are designed for long-range identification, often reaching several meters. These are typically used for vehicle gate access or large-scale warehouse tracking rather than person-to-door access.

2. Security Requirements and Chip Selection

Once you’ve determined the frequency, you must choose the specific chip. Not all RFID chips are created equal.

If security is your top priority, you should look for chips that support Advanced Encryption Standard (AES) or mutual authentication. For example, the MIFARE DESFire series is widely regarded as one of the most secure options on the market. On the other hand, if you are running a temporary event or a simple gym membership system, a basic "read-only" chip might suffice to keep costs down.

3. Material Matters: Durability vs. Sustainability

While standard PVC is the "go-to" material for most cards due to its durability and ease of printing, the industry is shifting toward more specialized and sustainable materials.

PVC and Composite Cards

Standard PVC cards are excellent for long-term use. If your project involves high-frequency usage—such as employee ID badges that are swiped or scanned dozens of times a day—durability is non-negotiable. Composite cards (a mix of PVC and PET) are even more heat-resistant, making them ideal for cards that undergo high-temperature lamination or re-transfer printing.

Eco-Friendly Alternatives

For events, exhibitions, or short-term access, many organizations are now opting for RFID paper cards. These cards offer a significant reduction in plastic waste while maintaining the same scanning functionality as their plastic counterparts. They are lightweight, cost-effective, and can be fully customized with high-quality graphics, making them perfect for single-use or short-duration applications.

4. Specialized Applications: The Hospitality Sector

The hospitality industry has unique requirements when it comes to RFID. In hotels, the card is not just a key; it is a branding tool and a guest's primary touchpoint with the facility's technology.

When selecting Hotel key cards, managers must balance aesthetic appeal with technical reliability. These cards need to integrate seamlessly with Property Management Systems (PMS) and electronic door locks (such as VingCard, Salto, or Dormakaba).

In addition to standard PVC, many luxury hotels are now exploring wooden RFID cards or recycled plastic options to align with their sustainability goals. Regardless of the material, the chip inside must be compatible with the specific encryption protocols of the hotel’s locking system.

5. Customization and Visual Identification

Choosing a "blank" card doesn't mean it has to stay blank. Most RFID projects require some level of visual customization. When ordering your cards, consider the following:

-

Surface Finish:Glossy finishes are standard, but matte finishes can provide a premium feel and are better at hiding fingerprints and scratches.

-

Printing Compatibility:Ensure the blank cards are "ISO compliant" so they can pass through standard thermal transfer or re-transfer card printers (like Fargo, Zebra, or Evolis) without jamming.

-

Security Features:To prevent counterfeiting, you can order cards with pre-printed holograms, UV ink patterns, or micro-text.

6. Technical Specifications Checklist

Before placing a bulk order, verify these technical details with your provider:

|

Feature

|

Consideration

|

|

Read Range

|

Does it meet the distance requirements of your readers?

|

|

Memory Size

|

Is there enough space to store user data or biometric templates?

|

|

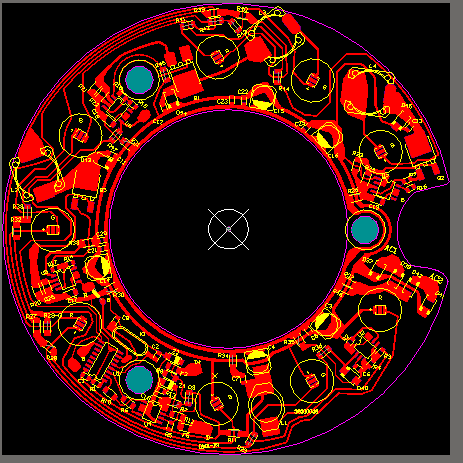

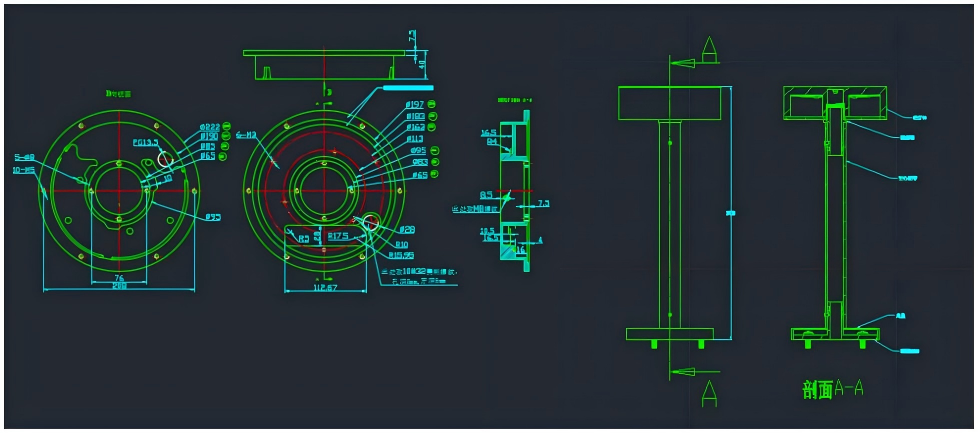

Antenna Design

|

Is the antenna optimized for the card's specific material?

|

|

Protocol

|

Does it follow ISO 14443A, ISO 15693, or other global standards?

|

7. How to Test Before You Buy

Never commit to a large-scale project without testing samples. RFID chips can behave differently depending on the environment. Metal surfaces, for instance, can interfere with the signal of standard RFID cards. If your readers are mounted on metal frames, you may need cards with specific tuning or spacers.

Request a sample pack of blank RFID cards and test them against every reader in your facility. Check for:

-

Read Speed:Does the gate open instantly, or is there a lag?

-

Consistency:Does the card work at different angles?

-

Physical Integrity:Does the card bend or snap easily under pressure?

Selecting the right RFID card is a balance of technology, environment, and budget. By understanding the differences between frequencies, choosing materials that suit the lifespan of the project—whether that’s durable PVC or eco-friendly RFID paper cards—and ensuring chip compatibility, you can build a robust and reliable access control system.

For specialized industries like hospitality, the right hotel key cards can even enhance the guest experience, merging security with brand identity. Take the time to audit your hardware, define your security level, and always test your samples.